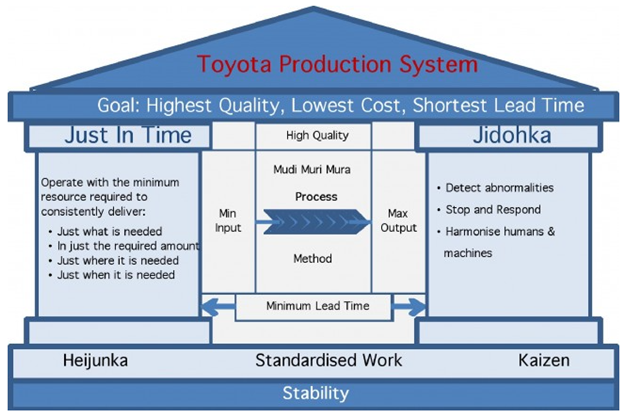

Once the worker halts production, a team leader would immediately go-see the issue by visiting the workstation. In Toyota’s view, employees not only had a right, but also an obligation to pull the cord if they discovered a problem with production. Jidoka, created by Toyota in the early 1900s, is one of the founding pillars of the Toyota Production System, and the Andon Cord is one of the most well-known examples of the concept at work. The Andon Cord is a product of Jidoka – a concept that empowers operators to detect abnormal conditions and immediately stop work. At Toyota, it was a tool to instill autonomic behavior patterns – what Rother calls Kata. Any front line worker could pull the rope to stop the manufacturing line at any time. Toyota implemented the Andon Cord as a physical rope that followed the assembly line.

But rather, the culture and specific behavior behind those tools. In the book, Toyota Kata – Mike Rother points out that it wasn’t the tools that made Toyota great. Anyone had the right to pull the cord at any time. When pulled, the rope would instantly stop all work on the assembly line. One of those tools was called the Andon Cord, also known as the Andon Board. His ideas produced an unprecedented run of quality and manufacturing success for over 40 years. Taiichi Ohno, the father of Toyota Production Systems (TPS), architected a leadership and technology model incorporating some of the original Jidoka ideas along with a lot of other interesting innovations. Amazon implemented the Andon Cord principle for customer service. Front-line workers can resolve quality or other issues by stopping production. This way, the production line would not manufacture any faulty units while working on fixing the problem as fast as possible. The Andon cord consists of a pull cord or button that workers could activate to stop the production and warn management in case of a significant issue. Today, many manufacturers use this invention in their assembly environments. Toyota introduced the Andon Cord concept in its factories following the Toyota Production System. This is a case of Amazon Andon Cord in action.Īndon (行灯) is a Japanese word that means paper lantern that the Japanese used for lighting since the Edo period. Amazon uses these measures to avoid shipping products with shortcomings that it is aware of. In addition, the product page is barred with the words - Item under review. Usually, these pertain to some products with some shortcomings that Amazon identified. Some sellers may receive an email from Amazon about Andon Cord. Andon Cord is a Japanese quality process that Amazon adopted to contain mistakes and maintain high customer satisfaction.

0 kommentar(er)

0 kommentar(er)